I. pōkole

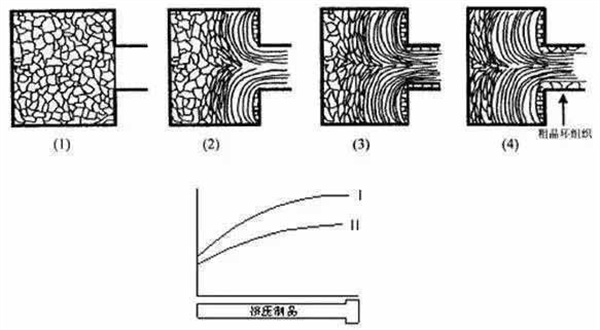

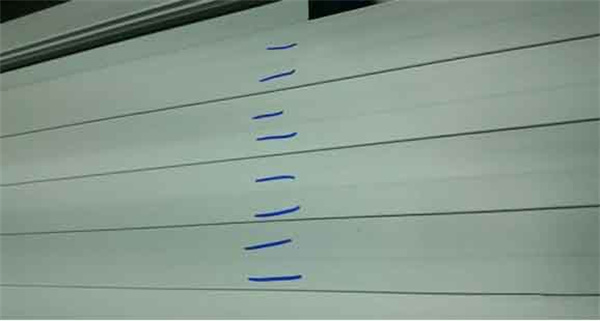

Ma ka hopena o ka huelo o kekahi mau huahana extruded, ma hope o ka nānā ʻana i ka hoʻonui haʻahaʻa, aia kahi ʻano like me ka pū ma ka ʻaoʻao waena o ka ʻāpana keʻa, i kapa ʻia ʻo shrinking tail.

ʻO ka mea maʻamau, ʻoi aku ka lōʻihi o ka huelo o ka huahana extrusion i mua ma mua o ka extrusion hoʻohuli, a ʻoi aku ka lōʻihi o ka alloy palupalu ma mua o ka paʻa paʻa.ʻO ka emi ʻana o ka huahana extruded mua ma ke ʻano o ka annular disjoint layer, a ʻo ka shrinkage o ka huahana extruded hoʻohuli ʻia ka hapa nui ma ke ʻano o kahi funnel waena.

Hoʻokuʻu ʻia ka metala i ka hope hope, a ʻo ka ʻili ingot a me nā inclusions haole i hōʻiliʻili ʻia ma ke kihi make o ka extrusion cylinder a i ʻole ke kahe ʻana o ka gasket i loko o ka huahana e hana i ka lua shrinkage;i ka wā pōkole loa ke koena mea a ʻaʻole lawa ke kikowaena o ka huahana, ʻo ke ʻano he ʻano o ka pōkole.Mai ka hopena o ka huelo a hiki i mua, e maʻalahi ka huelo a nalowale loa.

ʻO ke kumu nui o ka emi ʻana

1. He pōkole loa ka mea koena a i ʻole ka lōʻihi o ka ʻoki ʻia o ka huahana ʻaʻole i kūpono i nā lula;

2. ʻAʻole maʻemaʻe ka papa extrusion a loaʻa nā ʻaila ʻaila;

3. I ka wā hope o ka extrusion, ʻoi aku ka wikiwiki o ka extrusion a piʻi koke paha;

4. E hoʻohana i kahi ʻōpiʻi deformed (kahi i hoʻokiʻekiʻe ʻia ma ka waena);

5. He kiʻekiʻe loa ka mahana o ka cylinder extrusion;

6. ʻAʻole pili ka extrusion cylinder a me ka extrusion shaft;

7. ʻAʻole maʻemaʻe ka ʻili o ka ingot, aia nā ʻaila ʻaila, ʻaʻole i wehe ʻia nā maʻi koko a me ka pelu ʻana a me nā hemahema ʻē aʻe;

8. ʻAʻole maʻemaʻe a ʻino paha ka lima o loko o ka extrusion cylinder, a ʻaʻole i hoʻomaʻemaʻe ʻia ka ʻili o loko me kahi papa hoʻomaʻemaʻe i ka manawa.

ʻano pale

1. E waiho i ke koena a oki i na huelo e like me ka makemake;

2. E ho'oma'ema'e i nā po'i;

3. Hoʻonui i ka maikaʻi o ka ʻili o ka ingot;

4. Hoʻoponopono kūpono i ka mahana extrusion a me ka wikiwiki e hōʻoia i ka extrusion maʻalahi;

5. Ma waho aʻe o nā kūlana kūikawā, ua pāpā loa ʻia ke kau ʻana i ka ʻaila ma luna o ka ʻili o ka mea hana a me ka poni;

6. Hoʻomaʻalili pono ka gasket.

II.apo aniani kalakala

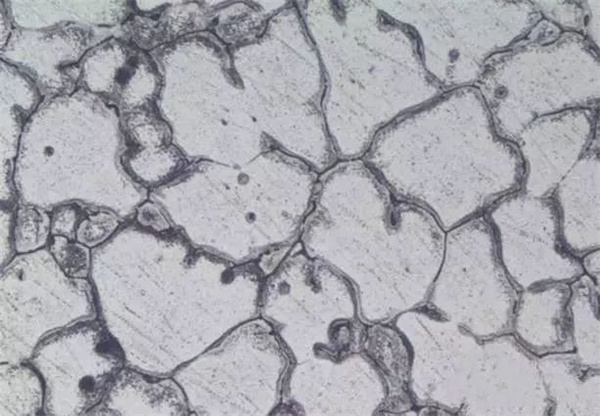

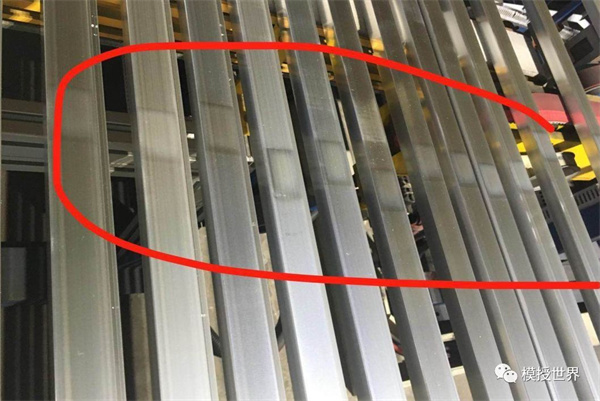

ʻO kekahi mau huahana i hoʻokuʻu ʻia i ka alumini alumini i hoʻokumu ʻia i kahi ʻāpana hoʻoheheʻe recrystallized ma ka ʻaoʻao o ka huahana ma ka ʻāpana hoʻāʻo haʻahaʻa haʻahaʻa ma hope o ka mālama ʻana i ka hopena, i kapa ʻia ʻo ke apo palaoa coarse.Ma muli o nāʻano likeʻole a me nāʻano hana o nā huahana, hiki ke hoʻokumuʻia ke apo, arc-shaped a me nāʻano'ē aʻe o nā apo.E emi mālie ana ka hohonu o ke apo koʻikoʻi mai ka huelo a i mua a nalowale loa.ʻO ka mīkini hoʻokumu mua ʻo ia ka ʻāpana sub-grain i hana ʻia ma ka ʻili o ka huahana ma hope o ka extrusion wela, a ua hoʻokumu ʻia ka ʻāpana palaoa recrystallized ma hope o ka hoʻomehana ʻana a me ka mālama ʻana.

ʻO ke kumu nui o ke apo kristal koʻikoʻi

1. Uneven extrusion deformation

2. He kiʻekiʻe loa ka mahana o ka mālama ʻana i ka wela a lōʻihi ka manawa paʻa, no laila e ulu aʻe nā hua;

3. ʻAʻole kūpono ke ʻano kemika o ke gula;

4. He mau apo ko'iko'i ma hope o ka ho'oma'ama'a 'ana i ka wela, 'o ia ho'i nā 'ano a me nā kaola o 6a02, 2a50 a me nā mea 'ē a'e, 'a'ole hiki ke ho'opau 'ia a hiki ke ho'omalu 'ia i loko o kekahi laulā;

5. He liʻiliʻi ka hoʻololi ʻana o ka extrusion a ʻaʻole lawa paha ka deformation, a i ʻole ma ke ʻano deformation koʻikoʻi, a maʻalahi ka hana ʻana i ke apo aniani.

ʻano pale

1. ʻO ka paia o loko o ka extrusion cylinder he maʻemaʻe a maʻemaʻe, e hana ana i kahi lima alumini piha e hoʻemi i ka friction i ka wā extrusion;

2. Pono ka deformation e like me ka piha a me ka like me ka hiki, a pono e mālama pono ʻia nā ʻāpana hana e like me ka mahana a me ka wikiwiki;

3. E hō'alo i ke ki'eki'e o ka wela o ka ho'oponopono 'ana a i 'ole ka lō'ihi o ka manawa pa'a;

4. Extrusion me ka porous make;

5. Hoʻokuʻu ʻia ma ke ʻano extrusion hoʻohuli a me ke ʻano extrusion static;

6. Hana ʻia e ka hoʻoponopono lāʻau-kauka-ke ʻano hana;

7. Hoʻoponopono i ka huina gula a hoʻonui i ka recrystallization inhibitory element;

8. E hoʻohana i ka extrusion wela kiʻekiʻe;

9. ʻAʻole homogenized kekahi mau ingots alloy, a pāpaʻu ke apo palaoa i ka wā extrusion.

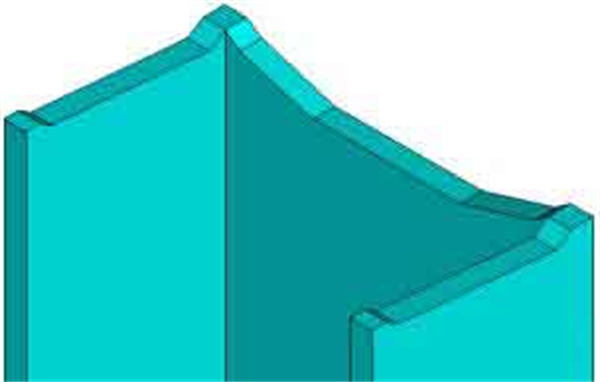

III, papa

ʻO kēia kahi kīnā delamination ʻili i hana ʻia i ka wā e ʻano like ke kahe o ka metala, a kahe ka ʻili o ka ingot i loko o ka huahana ma ke kikowaena ma waena o ka mold a me ka ʻāpana elastic hope.Ma ka ʻāpana hoʻāʻo haʻahaʻa haʻahaʻa transverse, ʻike ʻia aia kahi kīnā o nā papa like ʻole ma ka lihi o ka ʻāpana keʻa.

ʻO ke kumu nui o ka stratification

1. Aia ka lepo ma ka ʻili o ka ingot a i ʻole ka ingot he mau mea hoʻokaʻawale nui ma mua o ka ʻili kaʻa, nā ʻōpū metala, a me nā mea ʻē aʻe, he mea maʻalahi ke hana i nā papa;

2. Aia nā burrs ma ka ʻili o ka blank a i ʻole ka lepo e like me nā ʻaila ʻaila, sawdust, etc., ʻaʻole i hoʻomaʻemaʻe ʻia ma mua o ka extrusion;

3. ʻAʻole kūpono ke kūlana o ka lua make, kokoke i ka lihi o ka cylinder extrusion;

4. Hoʻohana koʻikoʻi ka mea hana extrusion a i ʻole he lepo i loko o ka bushing o ka extrusion cylinder, ʻaʻole hiki ke hoʻomaʻemaʻe a hoʻololi ʻia i ka manawa;

5. He nui loa ka ʻokoʻa anawaena o ka pā extrusion;

6. ʻOi aku ka kiʻekiʻe o ka mahana o ka extrusion cylinder ma mua o ka ingot.

ʻano pale

1. Hoʻolālā kūpono o nā mold, ka nānā ʻana i ka manawa a me ka hoʻololi ʻana i nā mea hana pono ʻole;

2. ʻAʻole hoʻokomo ʻia nā ingots pono ʻole i loko o ka umu;

3. Ma hope o ka ʻoki ʻana i ke koena mea, pono e hoʻomaʻemaʻe ʻia me ka ʻole o ka hoʻopili ʻana i ka ʻaila lubricating;

4. E mālama i ka uhi o ka extrusion cylinder i paʻa, a i ʻole e hoʻomaʻemaʻe i ka lining i ka manawa me ka gasket.

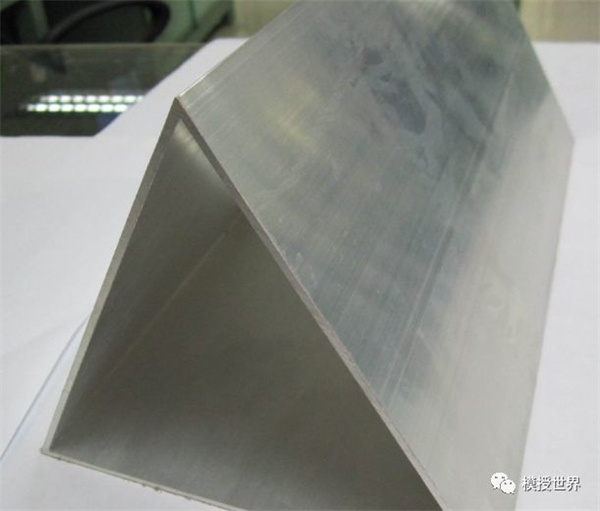

IV.ʻino ka wiliwili

ʻO ke ʻano o ka weld delamination a i ʻole ka hoʻopili piha ʻole ʻana o ka huahana hollow i hoʻokuʻu ʻia e ka make māhele ma ka weld i kapa ʻia ʻo ka welding maikaʻi ʻole.

ʻO ke kumu nui o ka wiliwili maikaʻi ʻole

1. He liʻiliʻi ka coefficient extrusion, haʻahaʻa ka mahana extrusion, a wikiwiki ka wikiwiki extrusion;

2. ʻAʻole maʻemaʻe ka hulu hipa extrusion a i ʻole nā mea hana;

3. E aila i ka poni;

4. ʻO ka hoʻolālā mold kūpono ʻole, lawa ʻole a i ʻole ke kaulike hydrostatic pressure, hoʻolālā kūpono ʻole o nā lua shunt;

5. Aia ka ʻaila hinu ma ka ʻili o ka ingot.

ʻano pale

1. Hoʻonui pono i ka extrusion coefficient, extrusion wela a me ka wikiwiki extrusion;

2. Hoʻolālā kūpono a me ka hana ʻana i nā mold;

3. ʻAʻole ʻaila a mālama ʻia ka ʻaila extrusion a me ka gasket extrusion;

4. E hoʻohana i nā ingots me nā wahi maʻemaʻe.

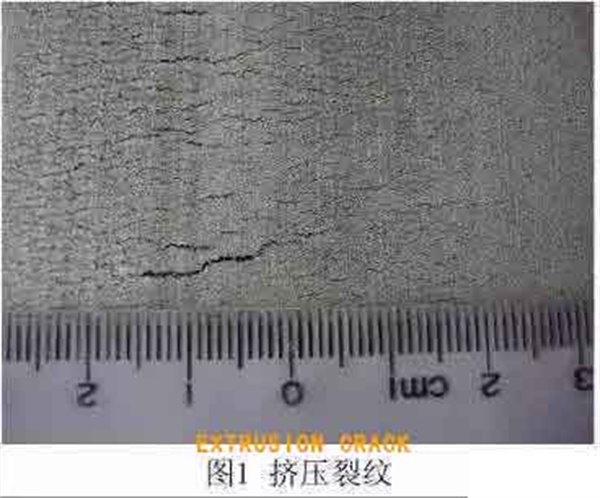

V. Nā māwae Extrusion

ʻO kēia ka liʻiliʻi arc-ʻano māwae ma ka lihi o ka transverse ho'āʻo'āpana o ka extruded huahana, a me ka manawa māwae ma kekahi kihi ma kona longitudinal kuhikuhi, i hunaia ma lalo o ka epidermis i malamalama hihia, a serrated māwae ma ka papa waho. i nā hihia koʻikoʻi, e hōʻino nui i ka hoʻomau o ka metala.Hoʻokumu ʻia nā māwae Extrusion i ka wā e wāwahi ʻia ai ka ʻili metala e ke koʻikoʻi tensile nui o ka pā make i ka wā o ke kaʻina extrusion.

ʻO ke kumu nui o nā māwae extrusion

1. He wikiwiki loa ka extrusion;

2. He kiʻekiʻe loa ka mahana extrusion;

3. ʻO ka wikiwiki extrusion fluctuates nui loa;

4. He kiʻekiʻe loa ka mahana o ka hulu hipa extruded;

5. Ke hoʻokuʻu ʻia ka porous die, ua kokoke loa ka hoʻonohonoho make i ke kikowaena, no laila ʻaʻole lawa ka lako metala waena, i nui loa ka ʻokoʻa ma waena o ke kikowaena a me ke kahe kahe o ka lihi;

6. ʻAʻole maikaʻi ka ingot homogenization annealing.

ʻano pale

1. Hoʻokō pono i nā ʻano kikoʻī hoʻomehana a me extrusion;

2. Nānā pinepine i nā mea hana a me nā mea hana e hōʻoia i ka hana maʻamau;

3. E hoʻololi i ka hoʻolālā mold a hoʻoponopono pono iā ia, ʻoi aku ka maikaʻi o ka hoʻolālā ʻana o ke alahaka mold, ke keʻena wili a me ka radius lihi, a me nā mea ʻē aʻe e kūpono;

4. E ho'ēmi i ka sodium ma loko o nā alumini alumini magnesium kiʻekiʻe;

5. Hoʻohui ʻia ka ingot a hoʻohui ʻia e hoʻomaikaʻi i kona plasticity a me ka like.

VI.ʻĀpana

Hoʻokaʻawale ʻia ka metala ʻili kūloko mai ka metala kumu, a hōʻike ʻia ʻo ia ma ke ʻano he pōʻai pōʻai hoʻokahi a i ʻole ke ʻano o ka ʻili i hoʻāla ʻia, i kapa ʻia he ʻūhū.

ʻO ke kumu nui o nā'ōhū

1. I ka extruding, i ka extrusion cylinder a me ka extrusion pad he lepo e like me ka wai a me ka aila;

2. Ma muli o ke komo ʻana o ka cylinder extrusion, e komo ka ea ma waena o ka ʻāpana a me ka ingot i ka ʻili metala i ka wā extrusion;

3. Aia ka wai i loko o ka lubricant;

4. Loaʻa nā hemahema o ka ingot ponoʻī a me ka porosity;

5. He kiʻekiʻe loa ka mahana mālama wela, lōʻihi ka manawa paʻa, a kiʻekiʻe ka haʻahaʻa o ka lewa i loko o ka umu;

6. He kiʻekiʻe loa ka ʻike hydrogen i loko o ka huahana;

7. He kiʻekiʻe loa ka mahana extrusion cylinder a me ka mahana ingot.

ʻano pale

1. Pono e hoʻomaʻemaʻe ʻia nā ʻili o nā mea paahana a me nā ʻāpana;

2. E hoʻolālā kūpono i ka nui like o ka extrusion cylinder a me ka extrusion gasket, e nānā i ka nui o ka mea hana pinepine, e hoʻoponopono i ka cylinder extrusion i ka manawa he ʻōpū nui, a ʻaʻole pono ka extrusion gasket ma waho o ka hoʻomanawanui;

3. E hōʻoia i ka maʻemaʻe a maloʻo ka lubricant;

4. E mālama pono i ke kaʻina hana extrusion, hoʻopau i ka manawa, ʻoki pololei, ʻaʻole e hoʻopili i ka ʻaila, hoʻopau loa i nā mea i koe, mālama i nā blanks a me nā mold maʻemaʻe a ʻaʻole haumia.

VII.ʻiliʻili

ʻO kēia ke ʻano o ka hoʻokaʻawale kūloko ma waena o ka metala ʻili a me ka metala kumu o ka huahana extrusion alloy aluminika.

ʻO ke kumu nui o ka peeling

1. Ke hoʻololi ʻia a hoʻokuʻu ʻia ka mea hao, hoʻopili ʻia ka paia o loko o ka extrusion cylinder i ka lāʻau i hana ʻia e ka metala kumu, ʻaʻole i hoʻomaʻemaʻe pono ʻia;

2. ʻAʻole i hoʻohālikelike pono ʻia ka cylinder extrusion a me ka papa extrusion, a ua hoʻopaʻa ʻia ka paia o loko o ka cylinder extrusion me ke koena metala kūloko;

3. Ua extruded e lubricating extrusion cylinder;

4. Aia ka metala ma ka puka make a lō'ihi loa ke kā'ei hana o ka make.

ʻano pale

1. E hoʻomaʻemaʻe pono i ka extrusion cylinder i ka wā e hoʻokuʻu ai i ka alloy;

2. Hoʻolālā kūpono i ka nui like o ka extrusion cylinder a me ka extrusion gasket, e nānā pinepine i ka nui o ka mea hana, a ʻaʻole hiki ke ʻae ʻia ka extrusion gasket;

3. E hoʻomaʻemaʻe i ke koena o ka metala ma ka ʻōpala i ka manawa.

VIII.Nā ʻōpala

Ua kapa ʻia nā ʻōpala mechanical i hoʻokaʻawale ʻia e ka pilina ma waena o nā mea ʻoi a me ka ʻili o ka huahana i ka wā e hoʻoheheʻe ai.

ʻO ke kumu nui o nā ʻōpala

1. ʻO ka hui kūpono ʻole o nā mea hana, nā alakaʻi a me nā papa hana, nā kihi ʻoi a i ʻole nā mea ʻē aʻe, a pēlā aku;

2. Aia nā ʻāpana metala ma ke kāʻei hana mold a i ʻole ke kāʻei hana mold i poino;

3. Aia ke one a i ʻole nā ʻāpana metala haki i loko o ka ʻaila lubricating;

4. ʻO ka hana kūpono ʻole i ka wā o ka lawe ʻana a me ka hoʻolaha pono ʻole.

ʻano pale

1. E nānā a poli i ke kāʻei hana poni i ka manawa;

2. E nānā i ke kahawai outflow o ka huahana, pono e maʻemaʻe, a hiki ke lubricated pono ke ala alakaʻi;

3. Kāohi i ka ʻānai ʻana a me ka ʻānai ʻana i ka wā e lawelawe ana.

IX.Puʻupuʻu

ʻO nā ʻōpala i hana ʻia ma ka ʻili o nā huahana a i ʻole nā huahana i hui pū ʻia me nā mea ʻē aʻe i kapa ʻia ʻo nā ʻeha puʻupuʻu.

ʻO ke kumu nui o nā puʻupuʻu

1. ʻAʻole kūpono ke ʻano o ka papa hana a me nā mea lāʻau;

2. Ka palekana metala kūpono ʻole o nā hīnaʻi waiwai, nā ʻeke waiwai, a pēlā aku;

3. Mai mālama pono i ka hana ʻana.

ʻano pale

1. Hana pono, lawelawe me ka malama;

2. E ʻoki i nā kihi ʻoi, a uhi i ka hīnaʻi a me ka pā me ka dunnage a me nā mea palupalu.

X. Nā ʻōpala

ʻO nā ʻōpala i puʻunaue ʻia ma ka ʻili o ka huahana ma muli o ka hoʻoheheʻe ʻana a i ʻole ka wehe ʻana ma hope o ka pili ʻana o ka ʻili o ka huahana extruded me nā ʻaoʻao a i ʻole nā ʻili o nā mea ʻē aʻe i kapa ʻia he scratches.

ʻO ke kumu nui o nā ʻōpala

1. Hoʻohana koʻikoʻi ka ʻōpala;

2. Ma muli o ke kiʻekiʻe o ka wela o ka ingot, pili ka puka make i ka alumini a i ʻole ke kāʻei hana o ka puka make;

3. ʻO ka lepo e like me ka graphite a me ka aila hāʻule i loko o ka extrusion cylinder;

4. Ke neʻe nei nā huahana me kekahi i kekahi, no laila ua ʻoki ʻia ka ʻili a me ke kahe o ka extrusion, ʻaʻole e kahe nā huahana i kahi laina pololei, e hopena i nā ʻōpala ma waena o ka mea a me ke ala alakaʻi a me ka papa hana.

ʻano pale

1. E nānā a hoʻololi i nā poni kūpono ʻole i ka manawa;

2. E hoomalu i ka wela wela o ka hulu hipa;

3. E hōʻoia i ka maʻemaʻe a maloʻo ka ʻili o ka extrusion cylinder a me ka hulu hipa;

4. E hoʻomalu i ka wikiwiki extrusion e hōʻoia i ka wikiwiki like.

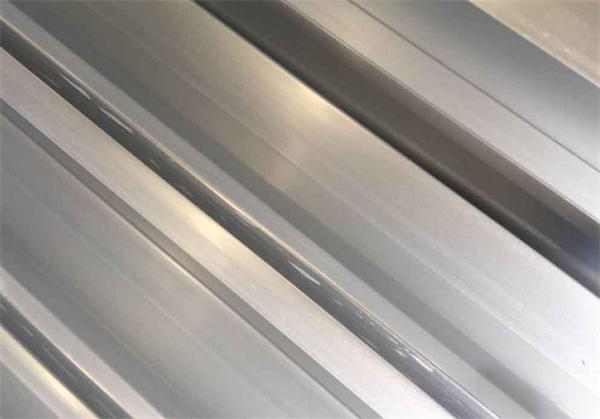

XI.Hoailona mold

He ʻano like ʻole kēia o ka longitudinal unevenness ma luna o ka ʻili o ka huahana extruded, a ʻo nā huahana extruded a pau ua make nā māka i nā pae like ʻole.

ʻO ke kumu nui o nā hōʻailona mold

ʻO ke kumu nui: ʻaʻole hiki i ke kāʻei hana mold ke hoʻokō i ka maʻalahi.

ʻano pale

1. E hōʻoia i ka maʻemaʻe o ka ʻili o ke kāʻei hana poni, maʻemaʻe a me ka ʻole o nā kihi ʻoi;

2. Hoʻomaʻamaʻa nitriding kūpono e hōʻoia i ka paʻakikī o ka ʻili kiʻekiʻe;

3. Hoʻoponopono pololei i ka ʻōpala;

4. Pono e hoʻolālā kūpono i ke kāʻei hana, a ʻaʻole lōʻihi loa ke kāʻei hana.

XII.wili, piko, nalu

ʻO ke ʻano i kapa ʻia ʻo ka wili ʻana o ka ʻāpana keʻa o ka huahana extruded ma ka ʻaoʻao longitudinal.ʻO ke ʻano o ka ʻāwili ʻana o ka huahana ma ka ʻaoʻao longitudinal a ʻaʻole pololei ke ʻano o ka pahi i kapa ʻia ʻo ka piko.ʻO ke ʻano undulating mau e kū ana ma ka ʻaoʻao longitudinal o ka huahana i kapa ʻia he nalu.

ʻO nā kumu nui o ka wili, ka piko, a me ka nalu

1. ʻAʻole maikaʻi ka hoʻolālā a me ka hoʻonohonoho ʻana o nā lua make, a i ʻole ka hoʻohele ʻana i ka nui o ke kāʻei hana i kūpono ʻole;

2. Poor machining pololei o ka make lua;

3. ʻAʻole i hoʻokomo ʻia ke alakaʻi kūpono;

4. Hoʻoponopono ponoʻole i ka poʻi;

5. ʻO ka mahana extrusion kūpono ʻole a me ka wikiwiki;

6. ʻAʻole i hoʻoponopono mua ʻia ka huahana ma mua o ka mālama ʻana i ka hopena;

7. ʻO ka hoʻoluʻu ʻole i ka wā o ka mālama wela ma ka pūnaewele.

ʻano pale

1. Kiʻekiʻe kiʻekiʻe o ka hoʻolālā mold a me ka hanaʻana;

2. E hoʻouka i kahi alakaʻi kūpono, traction a extrusion;

3. E hoʻohana i ka lubrication kūloko, hoʻoponopono a me ka hoʻololi a hoʻololi paha i ka hoʻolālā ʻana o ka lua shunt e hoʻoponopono i ka kahe o ka metala;

4. Hoʻoponopono kūpono i ka mahana extrusion a me ka wikiwiki e hana i ka deformation ʻoi aku ka like;

5. E ho'ēmi kūpono i ka wela o ka lāʻau hoʻonā a i ʻole e hoʻonui i ka mahana wai no ka lāʻau hoʻonā;

6. E hōʻoia i ka hoʻoluʻu ʻaʻahu i ka wā e hoʻopau ai i ka pūnaewele.

XIII.Piʻo paʻa

ʻO ke kuʻi koke ʻana o kahi huahana extruded ma kahi o ka ʻaoʻao lōʻihi i kapa ʻia he piko paʻakikī.

ʻO ke kumu nui o ke kulou paʻakikī

1. Unneven extrusion wikiwiki, hoʻololi koke mai ka haʻahaʻa māmā a hiki i ka wikiwiki kiʻekiʻe, a i ʻole ka hoʻololi koke ʻana mai ke kiʻekiʻe kiʻekiʻe i ka wikiwiki haʻahaʻa, a hoʻomaha koke;

2. Hoʻoneʻe rigidly i ka huahana i ka wā o ke kaʻina extrusion;

3. ʻAʻole kūlike ka ʻili hana o ka extruder.

ʻano pale

1. Mai hoʻokuʻu wale a hoʻololi koke i ka wikiwiki extrusion;

2. Mai hoʻoneʻe koke i ka profile me ka lima;

3. E hōʻoia i ka papaʻaina hoʻokuʻu ʻana a paʻa ka papa ʻaina hoʻokuʻu, me ka ʻole o nā mea ʻē aʻe, a ʻaʻole keakea ka huahana i hui ʻia.

XIV.Nai hemp

ʻO kēia ka hemahema o ka ʻili o ka huahana extruded, ʻo ia hoʻi, ʻo ka ʻili o ka huahana he mau flakes mau, nā ʻōpala kiko, nā lua, nā pi metala, a me nā mea like ʻole.

ʻO ke kumu nui o ka pockmark

1. ʻAʻole lawa ka paʻakikī o ka ʻōpala a i ʻole ka paʻakikī;

2. He kiʻekiʻe loa ka mahana extrusion;

3. He wikiwiki loa ka extrusion;

4. He lō'ihi loa ke kā'ei hana o ka po'i, 'o'ole'a a pa'a paha me ke metala;

5. He lōʻihi loa ka hulu hipa extruded.

ʻano pale

1. Hoʻonui i ka paʻakikī a me ka paʻakikī like ʻole o ke kāʻei hana mold;

2. E wela i ka extrusion cylinder a me ka ingot e like me nā lula, a hoʻohana i ka wikiwiki extrusion kūpono;

3. Hoʻolālā kūpono i ka ʻeleʻele, hoʻemi i ka ʻili o ka ʻili o ke kāʻei hana, a hoʻoikaika i ka nānā ʻana, hoʻoponopono a me ka polishing;

4. E hoʻohana i ka lōʻihi ingot kūpono.

XV.kaomi metala

I ka wā o ke kaʻina extrusion, kaomi ʻia nā ʻāpana metala i ka ʻili o ka huahana, i kapa ʻia ʻo ke kaomi metala.

ʻO nā kumu nui o ke komo ʻana o ka metala:

1. Ua hewa na wēlau huluhulu;

2. Hoʻopili ʻia ka ʻili o loko o ka huluhulu me ka metala a i ʻole ka ʻaila lubricating i nā ʻōpala metala a me nā lepo ʻē aʻe;

3. ʻAʻole i hoʻomaʻemaʻe ʻia ka cylinder extrusion, a aia nā ʻōpala metala ʻē aʻe;

4. Hoʻokomo ʻia ka ingot i loko o nā mea hao ʻē aʻe;

5. Aia ka slag i loko o ka hulu hipa.

ʻano pale

1. Wehe i na burrs ma ka hulu hipa;

2. E hōʻoia i ka maʻemaʻe a maloʻo ka ʻili o ka hulu hipa a me ka ʻaila lubricating;

3. E hoʻomaʻemaʻe i ka ʻōpala metala i loko o ka pahu a me ka extrusion cylinder;

4. E koho i ka hulu hipa kiʻekiʻe.

XVI.kaomi metala ʻole

ʻO nā mea ʻē aʻe e like me ka pōhaku ʻeleʻele e kaomi ʻia i loko o ka ʻili o loko a me waho o ka huahana extruded, i kapa ʻia ʻo non-metallic indentation.Ma hope o ka ʻoki ʻia ʻana o ka mea ʻē aʻe, e hōʻike ana ka ʻili o loko o ka huahana i nā puʻupuʻu o nā ʻano nui like ʻole, kahi e hoʻopau ai i ka hoʻomau o ka ʻili o ka huahana.

ʻO ke kumu nui o ke komo ʻana i ka non-metallic intrusion

1. ʻO ka nui o ka graphite particles he coarse or agglomerated, i loaʻa i ka makū a i ʻole ka ʻaila, a ʻaʻole kūlike ka hoʻoulu ʻana;

2. He haʻahaʻa ke kiko uila o ka ʻaila cylinder;

3. ʻAʻole kūpono ka lakio o ka ʻaila cylinder a me ka graphite, a he nui loa ka graphite.

ʻano pale

1. E hoʻohana i ka graphite kūpono a mālama i ka maloʻo;

2. E kānana a hoʻohana i ka ʻaila lubricating kūpono;

3. E mālama i ka lakio o ka aila lubricating a me ka graphite.

XVII.ʻAha ʻili

ʻO nā huahana extruded ʻaʻole i hana i ka mālama ʻana i ka ʻili, ka ʻili o ka huahana extruded, ma hope o ke kemika a i ʻole ka hopena electrochemical me ke ʻano o waho, ke kumu o ka pōʻino kūloko o ka ʻili, i kapa ʻia ʻo surface corrosion.Nalo ka ʻili o ka huahana ʻino i kona luster metala, a i nā hihia koʻikoʻi, hana ʻia nā huahana corrosion hina-keʻokeʻo ma ka ʻili.

ʻO ke kumu nui o ka ʻino o ka ʻili

1. Hōʻike ʻia ka huahana i nā media corrosive e like me ka wai, ka waikawa, ka alkali, ka paʻakai, a me nā mea ʻē aʻe i ka wā o ka hana ʻana, ka mālama ʻana a me ka lawe ʻana, a i ʻole i hoʻopaʻa ʻia i kahi ea humid no ka manawa lōʻihi;

2. ʻAʻole kūpono ka lākiō hui ʻana o ka alloy;

ʻano pale

1. E ho'oma'ema'e a malo'o ka ili o ka huahana a me ka hana a me ka waiho 'ana;

2. E hoʻomalu i ka maʻiʻo o nā mea i loko o ka hao.

XVIII.ʻAlani ʻili

ʻO ka ʻili o ka huahana extruded he uneven wrinkles e like me ka ʻili ʻalani, ʻike ʻia hoʻi he wrinkles surface.Hoʻokumu ʻia ia e nā ʻanoʻai koʻikoʻi i ka wā extrusion.ʻO ka ʻoi aʻe o ka ʻōpala, ʻoi aku ka maopopo o nā wrinkles.

ʻO ke kumu nui o ka ʻili ʻalani

1. ʻAʻole lawa ka ʻōnaehana ingot a ʻaʻole lawa ka mālama homogenization;

2. ʻAʻole kūpono nā kūlana extrusion, a ʻoi aku ka nui o nā hua o nā huahana i hoʻopau ʻia;

3. ʻO ka nui o ka hoʻopololei a me ka hoʻopololei he nui loa.

ʻano pale

1. Hoʻoponopono kūpono i ke kaʻina hana homogenization;

2. Pono ka deformation e like me ka hiki (e hoʻomalu i ka mahana extrusion, ka wikiwiki, etc.)

3. E hoʻomalu i ka nui o ka hoʻoponopono ʻana ʻaʻole i nui loa.

XIX.ʻAʻole like

Ma hope o ka extrusion, ʻike ʻia kahi concave a convex paha ka mānoanoa o ka huahana ma ka mokulele.ʻO ka maʻamau, ʻaʻole hiki ke nānā ʻia me ka maka ʻōlohelohe.Ma hope o ka mālama ʻana i ka ʻili, ʻike ʻia nā aka maikaʻi a i ʻole nā aka iwi.

ʻO ke kumu nui o ka like ʻole

1. ʻAʻole i hoʻolālā maikaʻi ʻia ke kāʻei hana mold, a ʻaʻole i hoʻonohonoho ʻia ka hoʻoponopono ʻana;

2. ʻAʻole kūpono ka nui o ka lua shunt a i ʻole ke keʻena mua, a ʻo ka ikaika o ka huki ʻana a i ʻole ka hoʻonui ʻana i ka ʻaoʻao ma ke keʻa e hoʻololi iki i ka mokulele;

3. ʻAʻole kūlike ke kaʻina hana hoʻoluʻu, a ua lohi ka wikiwiki hoʻoluʻu o ka ʻaoʻao paʻa paʻa a i ʻole ka ʻāpana intersecting, e hopena i nā degere like ʻole o ka emi ʻana a me ka deformation o ka mokulele i ka wā o ka hoʻoilo;

4. Ma muli o ka ʻokoʻa nui o ka mānoanoa, hoʻonui ʻia ka ʻokoʻa ma waena o ka ʻāpana pā mānoanoa a i ʻole ka hui wahi hoʻololi a me nā ʻāpana ʻē aʻe o ka hui.

ʻano pale

1. E hoʻomaikaʻi i ke kiʻekiʻe o ka hoʻolālā mold, hana a me ka hoʻoponopono ʻana;

2. E hōʻoia i ka māmā holo hoʻoluʻu like.

XX.Kūlana haʻalulu

ʻO kēia kahi hemahema streak maʻamau i ka ʻili o ka huahana extruded.Hōʻike ʻia ia e nā paʻi paʻi paʻa mau ma luna o ka ʻili o ka huahana, a ua kūlike ke ʻano o ke kāʻei hana me ke ʻano o ke kāʻei hana o ka mold, a i nā hihia koʻikoʻi, aia kahi manaʻo puʻupuʻu.

ʻO ke kumu nui o ka haʻalulu

1. Ke neʻe nei ke kumu extrusion i mua a haʻalulu ma muli o nā kumu mea hana, kahi e haʻalulu ai ka metala i ka wā e kahe ai i waho o ka lua;

2. Haalulu ka metala ke kahe mai ia mai loko mai o ka lua make ma muli o ka popopo;

3. ʻAʻole kūpono ka papa kākoʻo mold, ʻaʻole maikaʻi ka rigidity mold, a hiki ke haʻalulu i ka wā e loli ai ka mana extrusion.

ʻano pale

1. E hoʻohana i nā mole kūpono;

2. Pono e hoʻohana ʻia nā pads kākoʻo kūpono i ka wā i hoʻokomo ʻia ai ka mold;

3. Hoʻoponopono i nā mea hana.

XXI, Huipuia

ʻO ke kumu nui o ka hoʻokomo

No ka loaʻa ʻana o ka metala a i ʻole ka hoʻokomo ʻana i ka billet, ʻaʻole i loaʻa i ke kaʻina hana mua, a noho ma ka ʻili a i loko paha o ka huahana ma hope o ka extrusion.

ʻano pale

E hoʻoikaika i ka nānā ʻana o ka billet (me ka ultrasonic inspection) e pale aku i ka billet i loaʻa i nā metala a i ʻole nā mea hoʻohui ʻole mai ke komo ʻana i ke kaʻina extrusion.

XXII, Hoailona wai

ʻO ke keʻokeʻo keʻokeʻo a i ʻole ʻeleʻele ʻeleʻele ʻeleʻele nā kaha wai ma luna o ka ʻili o ka huahana i kapa ʻia he wai.

ʻO ke kumu nui o nā hōʻailona wai

1. ʻAʻole maikaʻi ka maloʻo ʻana ma hope o ka hoʻomaʻemaʻe ʻana, a aia ke koena o ka wai ma luna o ka ʻili o ka huahana;

2. ʻAʻole i hoʻomaʻemaʻe ʻia ke koena o ka wai ma luna o ka ʻili o ka huahana e ka ua a me nā kumu ʻē aʻe;

3. Aia ka wai i ka wahie o ka umu kahiko, a ua hoʻohāinu ka wai ma luna o ka ʻili o ka huahana i ka wā e hoʻomaha ai ka huahana ma hope o ka ʻelemakule;

4. ʻAʻole maʻemaʻe ka wahie o ka umu kahiko, a ua ʻino ʻia ka ʻili o ka huahana e ka sulfur dioxide ma hope o ka puhi ʻana a i ʻole ka haumia e ka lepo;

5. Ua haumia ka mea kinai.

ʻano pale

1. E mālama i ka ili o ka huahana i maloʻo a maʻemaʻe;

2. E hoʻomalu i ka makū a me ka maʻemaʻe o ka uku ʻelemakule;

3. E hoʻoikaika i ka hoʻokele ʻana i ke ʻano hoʻopiʻi.

XXIII.ʻO ke āpau

Hoʻopili ʻia ka lula ma luna o kahi mokulele o ka huahana extruded, a aia kekahi ʻokoʻa ma waena o ka mōʻī a me ka ʻili, i kapa ʻia he āpau.

ʻO ke kumu nui o ka hakahaka

Kahe metala ʻole i ka wā extrusion a i ʻole ka hoʻopau pono ʻole a me ka hoʻoponopono pololei ʻana.

ʻano pale

E hoʻolālā a hana i nā mold ma ke kūpono, e hoʻoikaika i ka hoʻoponopono ʻana i ka mold, a mālama i ka mahana extrusion a me ka wikiwiki extrusion e like me nā lula.

XXIV, Ka mānoanoa pā like ʻole

ʻO nā huahana i hoʻokuʻu ʻia o ka nui like he mau paia lahilahi a mānoanoa paha ma ka ʻāpana like a i ʻole ka longitudinal kuhikuhi, a ua kapa ʻia kēia ʻano he mānoanoa pā ʻole.

ʻO ke kumu nui o ka mānoanoa pā

1. ʻAʻole kūpono ka hoʻolālā ʻana o ka mold, a i ʻole ke kūpono o ka mea hana a me ka hui ʻana;

2. ʻAʻole ma ka laina waena ka extrusion cylinder a me ka nila extrusion, e hana ana i ka eccentricity;

3. Hoʻohana nui ʻia ka uhi o ka cylinder extrusion, a ʻaʻole hiki ke hoʻopaʻa paʻa ʻia ka ʻōpala, e hopena i ka eccentricity;

4. ʻAʻole hiki ke hoʻopau ʻia ka mānoanoa pā like ʻole o ka ingot blank ma hope o ka extrusions mua a me ka lua.ʻAʻole hoʻoneʻe ʻia ka mānoanoa paʻa ʻole o ka hulu hipa ma hope o ka extrusion ma hope o ka ʻōwili ʻana a me ke kau ʻana;

5. Hoʻohana pono ʻole ʻia ka ʻaila lubricating, kahi e kahe ʻole ai ka metala.

ʻano pale

1. E hoʻonui i ka hoʻolālā a me ka hana ʻana i nā mea hana a me nā mold, a hoʻonohonoho pono a hoʻoponopono;

2. Hoʻoponopono i ke kikowaena o ka extruder a make ka extrusion;

3. E koho i nā hakahaka kūpono;

4. Ka mana kūpono o ka wela extrusion, ka wikiwiki extrusion a me nā ʻāpana kaʻina hana ʻē aʻe.

XXV.Hoʻonui (a) waha

ʻO ka hemahema o nā ʻaoʻao ʻelua o nā huahana extruded profile e like me ka groove a me ka I-shaped i hili ʻia i waho i kapa ʻia ʻo flaring, a ʻo ka hemahema i komo i loko ua kapa ʻia ʻo ia ka wehe ʻana.

ʻO nā kumu nui o ka hoʻonui (consolidation)

1. ʻAʻole kūlike ka holo kahe metala o nā "wāwae" ʻelua (a i ʻole hoʻokahi "wāwae") o ka pā a i ʻole nā ʻaoʻao o ka pahu like ʻole a i ʻole nā ʻaoʻao I-like;

2. ʻAʻole kūlike ka kahe kahe o ke kāʻei hana ma nā ʻaoʻao ʻelua o ka pā lalo lalo;

3. ʻO ka mīkini hoʻopololei kikoo kūpono ʻole;

4. Ma hope o ka puka ʻana o ka huahana mai loko mai o ka lua mold, ʻaʻole i hoʻomaʻamaʻa maikaʻi ʻia ka lāʻau lapaʻau online.

ʻano pale

1. Hoʻomalu pono i ka wikiwiki extrusion a me ka mahana extrusion;

2. E hōʻoia i ka lokahi o ka hoʻoilo;

3. Hoʻolālā pololei a hana i nā poni;

4. E hoʻomalu pono i ka mahana extrusion a me ka wikiwiki, a hoʻokomo i ka mea hana a make pono.

XXVI.Hoʻopololei i nā kaha

ʻO nā kaha helical i hana ʻia i ka wā i hoʻopololei ʻia ai ka ʻōwili luna o ka huahana extruded i kapa ʻia he mau māka hoʻoponopono, a ʻaʻole hiki ke pale ʻia nā kaha hoʻopololei no kekahi huahana i hoʻopololei ʻia e ka ʻōwili luna.

ʻO ke kumu nui o ka hoʻopololei ʻana i nā kaha

1. Aia nā ʻaoʻao ma ka ʻili o ka huila hoʻopololei;

2. Nui loa ka piko o ka huahana;

3. Nui loa ke kaomi;

4. He nui loa ka huina o ka wili pololei

5. He ovality nui ka huahana.

ʻano pale

E lawe i nā hana kūpono e hoʻoponopono e like me ke kumu.

XXVII.ʻO nā māka hoʻomaha, nā manaʻo koke, nā māka nahu

Hoʻopau i ka extrusion i ka wā extrusion e hana i nā kaha ma luna o ka ʻili o ka huahana a kū pololei i ke kuhikuhi extrusion, i kapa ʻia nā kaha hoʻomaha;nā kaha laina a i ʻole ka ʻili ma ka ʻili o ka huahana a kū pololei i ka ʻaoʻao extrusion i ka wā o ka extrusion, i ʻike ʻia ʻo nā māka nahu a i ʻole nā manaʻo hikiwawe (i kapa ʻia ʻo "fake parking marks")

I ka wā o ka extrusion, ua hoʻokaʻawale koke ʻia nā mea hoʻopili i hoʻopili paʻa ʻia i ka ʻili o ke kāʻei hana a pili i ka ʻili o ka huahana extruded e hana i nā ʻano.ʻO nā kaha ākea o ke kāʻei hana i ʻike ʻia i ka wā i hoʻōki ʻia ai ka extrusion i kapa ʻia nā māka kaʻa;kapa ʻia nā ʻōpala i ʻike ʻia i ka wā o ka extrusion he manaʻo koke a i ʻole nā hōʻailona nahu, a e kani lākou i ka wā extrusion.

ʻO nā kumu nui o nā kaha hoʻomaha, nā kaha koke, a me nā māka nahu

1. Unneven wela wela o ka ingot a i ʻole hoʻololi koke i ka wikiwiki extrusion a me ke kaomi;

2. Hoʻolālā maikaʻi ʻole ʻia a hana ʻia nā ʻāpana nui o ka ʻōpala, a i ʻole ka hui ʻana a he mau hakahaka;

3. Aia kekahi mana o waho e kū pono ana i ke kuhikuhi extrusion;

4. ʻAʻole holo mālie ka extruder, a aia kahi hanana o ke kolo.

ʻano pale

1. ʻO ka wela kiʻekiʻe, ka wikiwiki wikiwiki a me ka extrusion like ʻole, paʻa ka ikaika extrusion;

2. Kāohi i ka ikaika o waho i ke kuhikuhi extrusion vertical mai ka hana ʻana i ka huahana;

3. ʻO ka hoʻolālā kūpono o nā mea hana a me nā mea hoʻoheheʻe, koho pololei i nā mea hoʻoheheʻe, ka nui o ka nui, ka ikaika a me ka paʻakikī.

XXVIII.Nā ʻōpala ma ka ʻili o loko

Ua kapa ʻia nā ʻōpala ma ka ʻili o loko o ka huahana extruded i ka wā o ka extrusion.

ʻO ke kumu nui o ka abrasion o loko

1. Hoʻopili ʻia ka nila extrusion me ke metala;

2. He haʻahaʻa ka mahana o ka nila extrusion;

3. He ʻilihune ka maikaʻi o ka ʻili o ka nila extrusion a aia nā puʻupuʻu;

4. ʻAʻole mālama maikaʻi ʻia ka mahana extrusion a me ka wikiwiki;

5. Laki ole pono ole o ka lubricant extrusion;

ʻano pale

1. Hoʻonui i ka mahana o ka extrusion cylinder a me ka nila extrusion, a mālama i ka mahana extrusion a me ka wikiwiki extrusion;

2. E hoʻoikaika i ka kānana aila lubricating, e nānā a hoʻololi pinepine i ka ʻaila ʻōpala, a hoʻopili i ka aila me ka like a me ke kūpono;

3. E ho'oma'ema'e i ka hulu hipa;

4. E hoʻololi i nā ʻeleʻele kūpono ʻole a me nā nila extrusion i ka manawa, a mālama i ka ʻili o nā mold extrusion maʻemaʻe a maʻemaʻe.

XXX.Nā kumu ʻē aʻe

Ma kahi huaʻōlelo, ma hope o ka hoʻomaʻamaʻa piha ʻana, hiki ke hoʻopau maikaʻi ʻia nā ʻano kīnā 30 o nā huahana extrusion alumini alumini i ʻōlelo ʻia ma luna, kiʻekiʻe kiʻekiʻe, kiʻekiʻe kiʻekiʻe, lōʻihi ke ola, a me ka ʻili o ka huahana nani, e hana ana i kahi hōʻailona, e lawe mai i ke ola a me ka pōmaikaʻi i ka ʻoihana, a me ka loaʻa ʻana o nā pono ʻenehana a me ka waiwai.

XXX.Nā kumu ʻē aʻe

Ma kahi huaʻōlelo, ma hope o ka hoʻomaʻamaʻa piha ʻana, hiki ke hoʻopau maikaʻi ʻia nā ʻano kīnā 30 o nā huahana extrusion alumini alumini i ʻōlelo ʻia ma luna, kiʻekiʻe kiʻekiʻe, kiʻekiʻe kiʻekiʻe, lōʻihi ke ola, a me ka ʻili o ka huahana nani, e hana ana i kahi hōʻailona, e lawe mai i ke ola a me ka pōmaikaʻi i ka ʻoihana, a me ka loaʻa ʻana o nā pono ʻenehana a me ka waiwai.

Ka manawa hoʻouna: ʻAukake-14-2022